What is a Reamer? Essential Tool Explained

What is a Reamer? Essential Tool Explained

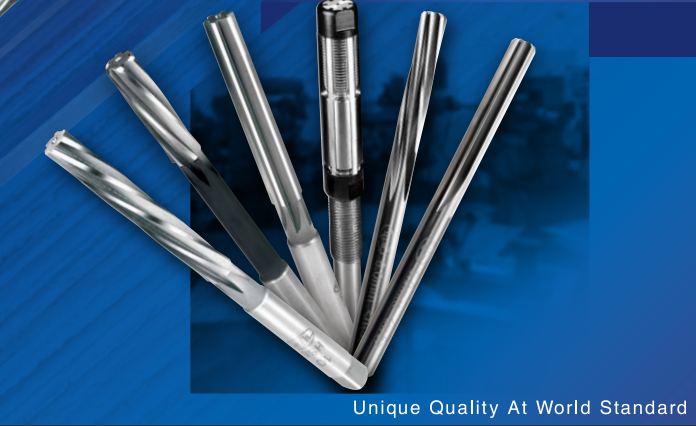

In the world of manufacturing and engineering, cutting tools are key. The reamer is one such tool, used to enlarge or shape holes in materials. It's vital in many fields, like automotive and aerospace, where precision matters a lot.

Reamers are a must-have in today's manufacturing. They help make complex parts with exact hole sizes and shapes. This tool has changed how we design and make products, making them better and faster to produce.

Reamers are very important in making things today. They help make parts that are just right. In the world of making things and engineering, reamers are a big deal. They play a big role in making high-quality products.

Key Takeaways

- Reamers are a type of cutting tool used to enlarge or shape holes in materials.

- They are essential in various manufacturing and engineering applications, including automotive and aerospace.

- Reamers enable the creation of complex components with precise hole sizes and shapes.

- The use of reamers has revolutionized the production process in modern manufacturing.

- Reamers are a crucial component in the production of high-quality components with increased efficiency.

Understanding the Basics of Reamers

Reamers are key in precision engineering, offering accurate results in various machining tasks. They enlarge holes to precise diameters, ensuring a smooth finish. This is crucial for parts to fit perfectly, enhancing machine performance and reliability.

In machining, reamers help achieve high precision and accuracy. They are used after drilling to refine holes and reach the desired diameter. Understanding their design and functionality is essential for their use.

Reamers are known for their high levels of precision and accuracy. They are also durable, lasting long and needing less replacement. With various sizes and types, they fit a wide range of applications and industries.

Reamers stand out from other cutting tools. While drills and mills remove material, reamers refine holes for precise diameters. This makes them vital in precision engineering, where accuracy is key.

Types of Reamers in Modern Manufacturing

In manufacturing, engineering is key in creating tools like reamers. Reamers help enlarge or shape holes in metal. They come in different types, each for a specific use.

There are hand reamers, machine reamers, and expansion reamers. Hand reamers are great for small, precise work. Machine reamers are better for big, fast jobs. Expansion reamers are for making holes bigger without wasting too much material.

Choosing the right reamer in manufacturing depends on the project's needs. This includes the material, hole size, and precision needed. Knowing each reamer's role helps engineering pros make better choices.

Using the right reamer can greatly improve a product's quality and efficiency. By picking the best reamer, manufacturers can make products that are precise and high-quality. This boosts their reputation and competitiveness in the market.

Common Applications and Uses

Reamers are key in many fields like automotive, aerospace, and machining. They help make products with exact sizes and smooth surfaces. In car making, they're used for engine parts like cylinder blocks and gearboxes.

In space tech, reamers help craft complex parts like engine blades and landing gear. They're also vital in general machining for making various components. Using reamers boosts product quality, saves time, and cuts costs.

Key Industries That Rely on Reamers

- Automotive industry: engine components, gearboxes, and transmission parts

- Aerospace industry: engine turbine blades, landing gear components, and other complex parts

- General machining operations: production of simple and complex components, including assemblies and sub-assemblies

Reamers are crucial in these areas. They help make top-notch products with exact sizes and smooth finishes. This is why they're essential in car, space, and machining fields. They ensure complex parts are made accurately and efficiently, saving money too.

What is a Reamer's Role in Precision Engineering?

Precision engineering needs high accuracy and detail in machining. Reamers are key in making precise parts. They use cutting tools to get exact sizes and shapes.

Reamers mainly make holes bigger to exact sizes. This is vital for parts that need to fit just right. They remove a bit of material to control the hole's size.

Using reamers in precision engineering has many benefits. These include:

- Improved accuracy: Reamers help make parts with exact sizes and shapes.

- Increased efficiency: Reamers make making complex parts faster and easier.

- Enhanced surface finish: Reamers create a smooth surface, which is important in precision engineering.

As precision engineering grows, reamers will keep being important. Knowing how reamers help makes machining better. This leads to making high-quality parts with precision.

Selecting the Right Reamer for Your Project

Choosing a reamer involves looking at material selection, size, and tolerance. You want a reamer that fits your project's needs for accuracy and efficiency. It's also important to do a cost-benefit analysis to compare different reamers.

Material type is a big factor in material selection. The wrong reamer can ruin your work. For instance, a steel reamer won't work well with aluminum. You also need to think about size and tolerance for precision.

Here are some key things to think about when picking a reamer:

- Material compatibility

- Size and tolerance requirements

- Cost and budget

- Project specific needs

Doing a good cost-benefit analysis helps you decide. Think about the costs and benefits of each reamer. Also, consider how long the reamer will last and what maintenance it needs.

Maintenance and Care Guidelines

Proper maintenance and care are key to keeping reamers in good shape. Regular checks and upkeep can spot problems early. To keep your reamers working well, follow these easy steps.

First, keep your reamers in a dry, clean spot, away from sunlight and moisture. This stops rust and corrosion, which harm the cutting edges. Then, clean them regularly with a soft cloth and mild soap to remove dirt and grime. This keeps the reamer sharp and accurate.

For reamer maintenance, always check for wear and damage. Look for chips or cracks and replace the reamer if you find any. By doing these simple things, you can make your reamers last longer and work better.

Some important tips for maintenance and care are:

- Regularly inspecting your reamers for signs of wear and tear

- Storing your reamers in a dry, clean environment

- Establishing a regular cleaning schedule

- Checking for damage and replacing the reamer as needed

Conclusion: Maximizing Your Reamer's Potential

Reamers are key in precision engineering. They help make products with tight tolerances and high-quality finishes. By choosing the right

Working in the automotive, aerospace, or other precision manufacturing fields? Using reamers can put you ahead of the competition. Spend time learning about reamer selection, care, and use. This will help you achieve results that impress your customers.

FAQ

What is a reamer and what are its core functions?

A reamer is a tool used to enlarge or shape holes in metal or other materials. It's key in many fields like automotive, aerospace, and machining. Reamers help make holes with tight tolerances and smooth finishes.

How do reamers differ from other cutting tools?

Reamers are different from other tools like drills. They enlarge or refine holes, not create new ones. They have multiple cutting edges for precise and uniform holes. This makes them vital for precision engineering.

What are the basic components of a reamer?

A reamer has a shank, flute, and cutting edge. The shank fits into machines, the flute removes chips, and the cutting edge removes material.

What are the different types of reamers used in modern manufacturing?

Modern manufacturing uses hand, machine, and expansion reamers. Hand reamers are for small tasks, machine reamers for CNC operations, and expansion reamers for enlarging holes.

What are the common applications and uses of reamers?

Reamers are used in many industries. In the automotive field, they make precise holes for engine parts. In aerospace, they're key for high-precision components. They're also used in general machining for tight tolerances and smooth finishes.

What is the role of reamers in precision engineering?

Reamers are crucial in precision engineering. They create holes with tight tolerances and smooth finishes. This ensures the accuracy and quality of products, especially in aerospace.

How can I select the right reamer for my project?

Choosing the right reamer depends on several factors. Consider the material, hole size, tolerance, and cost. Pick a reamer that meets your project's needs and fits your budget.

What are the maintenance and care guidelines for reamers?

Proper care extends a reamer's life. Regularly inspect, clean, and store them in a dry place. Handle them carefully to avoid damage. Following these guidelines ensures their performance and longevity.