Quality Reamer Manufacturers: Trusted Solutions for Your Project

Quality Reamer Manufacturers: Trusted Solutions for Your Project

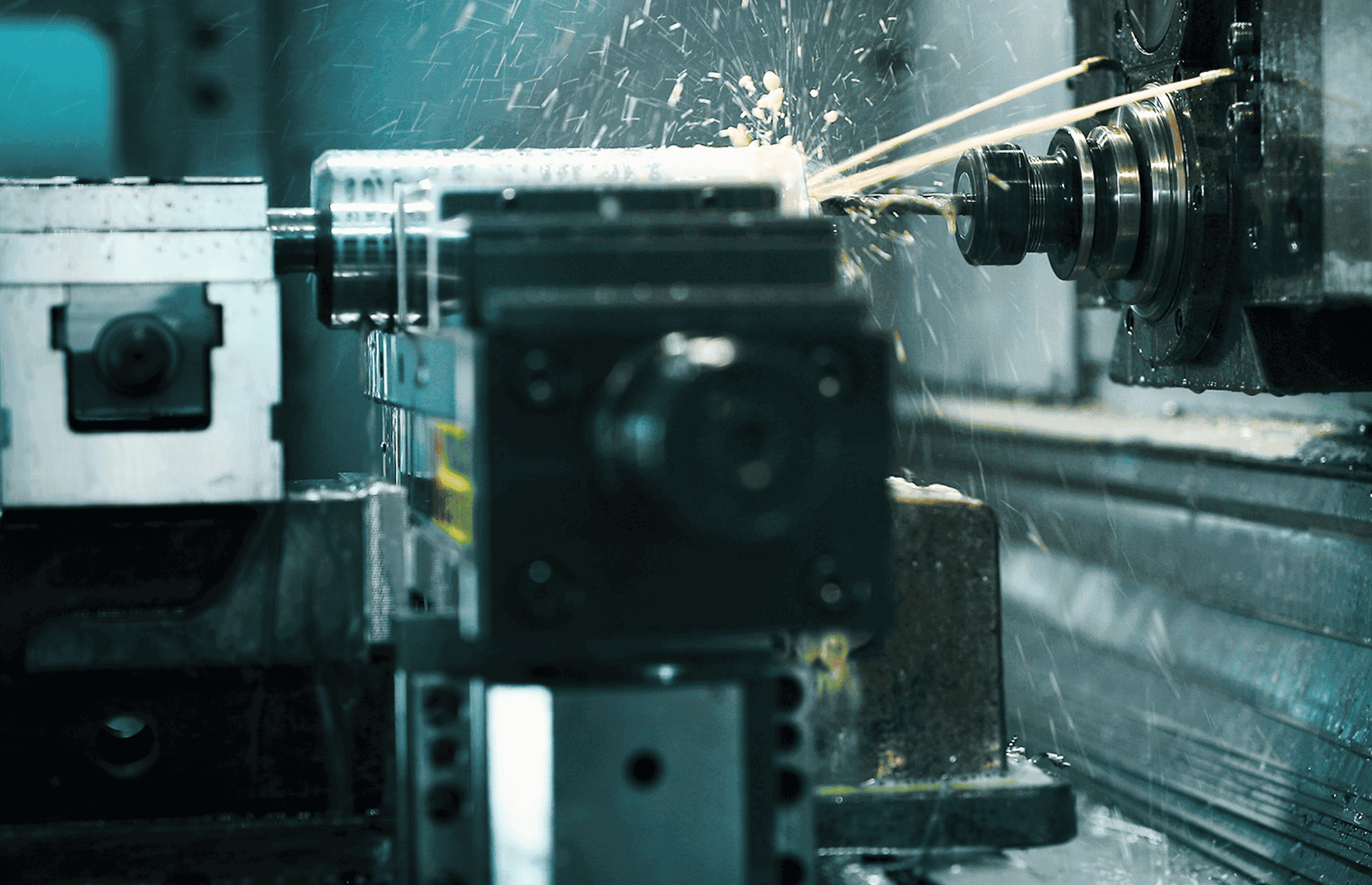

Finding the right reamer manufacturers is key for your project's success. Precision reamers are essential for the accuracy and quality of your final product. Reamer manufacturers specialize in making high-quality precision reamers for various industrial needs. This article will delve into the world of reamer manufacturers and highlight the importance of precision reamers in industrial reaming.

Industrial reaming demands precision and accuracy. Reamer manufacturers have stepped up by offering innovative solutions. They provide everything from precision reamers to custom-made reaming tools. Their expertise and advanced technology make them reliable partners for businesses in the United States.

Introduction to Reamer Manufacturers

Reamer manufacturers have honed their skills, offering top-quality precision reamers that meet the highest standards. Their dedication to excellence has made them trusted solutions providers in the industry. Whether you need standard or custom reaming solutions, reamer manufacturers have the knowledge and resources to deliver.

Key Takeaways

- Reamer manufacturers provide high-quality precision reamers for industrial reaming

- Precision reamers are crucial for ensuring accuracy and quality in industrial reaming

- Reamer manufacturers offer custom-made reaming tools and solutions

- Industrial reaming requires precision and accuracy, making reamer manufacturers essential partners

- Reamer manufacturers have revolutionized the industry with innovative solutions and state-of-the-art technology

- Reamer manufacturers are trusted solutions providers, committed to delivering exceptional quality and performance

Understanding Modern Reamer Manufacturing Excellence

Modern reamer manufacturing has seen big changes, focusing on precision and quality. The industry now offers a wide range of custom reaming solutions to meet different needs. Advanced technologies help make high-quality reaming tools that fit specific needs.

The making of precision reamers follows strict standards and quality checks. This makes sure the final products are accurate, reliable, and last long. Key factors that make modern reamer manufacturing great include:

- Advanced materials and coatings

- Precision machining and grinding techniques

- Stringent quality control and inspection processes

Reamer manufacturers use these factors to make top-notch reaming tools. These tools are crucial for various industries. They help improve efficiency and accuracy in manufacturing, making them vital today.

| Type of Reamer | Application | Benefits |

|---|---|---|

| Hand Reamer | General-purpose machining | Portability and ease of use |

| Machine Reamer | Precision machining and production | High accuracy and efficiency |

| Specialty Reamer | Custom and specialized applications | Unique features and capabilities |

In conclusion, modern reamer manufacturing has reached new heights. It focuses on precision, quality, and custom reaming solutions. Knowing about the different precision reamers and quality standards helps industries choose the right reaming tools for their needs.

Leading Reamer Manufacturers in the United States

The United States is a hub for top reamer manufacturers. They specialize in industrial reaming and precision reamers. These companies are known for their quality products and excellent service.

Reamer manufacturers in the US focus on precision. They use advanced technologies to ensure their products are top-notch. They offer a variety of reamers for different industries and needs.

Some of the key services offered by leading reamer manufacturers in the US include:

- Custom reamer design and manufacturing

- Precision reamer repair and maintenance

- Industrial reaming services for various industries

- Consultation and technical support for reamer selection and application

Reamer manufacturers in the US aim to provide exceptional quality and service. They are a reliable choice for industries that need precision reamers. By choosing a reputable manufacturer, businesses can get high-quality products that meet their needs.

| Manufacturer | Location | Specialization |

|---|---|---|

| Manufacturer 1 | New York | Precision Reamers |

| Manufacturer 2 | California | Custom Reamers |

| Manufacturer 3 | Texas | Industrial Reaming |

Essential Features of Premium Quality Reamers

Premium quality reamers offer top-notch performance and accuracy in many industrial settings. The quality of reaming tools greatly affects the success of a project. We will look at key features of these reamers, like material, precision, and surface finish.

Top-notch reamers are built from tough materials for long-lasting use. Precision reamers ensure accurate results, perfect for projects needing tight tolerances. Also, custom reaming solutions can be tailored to fit specific project needs.

Material Composition and Durability

The material of a reamer is key to its durability and performance. Premium reamers use high-quality materials for industrial use. Some important features include:

- High-speed steel or carbide for extra durability

- Advanced coatings for better wear resistance

- Precision grinding and polishing for smooth finishes

Precision Tolerances and Accuracy

Precision and accuracy are vital in many industrial uses of reamers. Premium quality reamers deliver precise results, ideal for projects needing tight tolerances.

Custom Solutions from Top Reamer Manufacturers

Reamer manufacturers create custom solutions for different industries. These solutions are made for precise and efficient results. They are perfect for industrial reaming needs. Top reamer makers offer tailored solutions that fit each client's unique needs.

Custom reaming solutions have many benefits. They offer increased precision, improved efficiency, and reduced costs. Working with a trusted reamer maker ensures high-quality and precise solutions. This is crucial in industries like aerospace and automotive.

Top reamer manufacturers provide many services. They design, develop, and produce custom reamers. Their services aim to give clients a complete solution that fits their needs. Some key services include:

- Custom reamer design and development

- Precision reaming solutions for industrial applications

- High-quality reamer production and manufacturing

Choosing a reputable reamer manufacturer ensures quality and precision. This boosts efficiency, cuts costs, and increases productivity in industrial reaming. With their expertise, top reamer manufacturers offer custom solutions that meet each client's specific needs.

Industry Applications and Specialized Requirements

Precision reamers are key in many fields like automotive, aerospace, and medical device making. They need to be very precise and accurate. This is because making precise holes and surfaces is crucial in these areas.

In the automotive and aerospace fields, reamers help make precise holes for important parts. This ensures parts work better and last longer. For instance, in cars, they make holes for engine cylinders. In planes, they help with engine parts.

In medical device making, precision reamers are vital. They help create precise holes and surfaces for implants and tools. This ensures medical devices are safe and work well. Some uses include:

- Creating precise holes for surgical tools

- Manufacturing medical implants with precise surfaces

- Producing medical devices with precise tolerances

Overall, precision reamers meet specific needs in many industries. They are essential for making parts that perform well and last. This is why they are so important.

Selecting the Right Manufacturer for Your Reaming Needs

Choosing the right reamer manufacturer is key. They offer custom solutions, from precision reamers to specialized tools. Look at their capabilities, experience, and reputation to make the right choice.

Quality is important, but so is the level of service. A good manufacturer will offer custom solutions, technical support, and quick customer service. They should also guide you on the best tools and techniques for your project.

Here are some important factors to consider:

- Experience and expertise in producing high-quality precision reamers

- Ability to provide custom reaming solutions tailored to your specific needs

- Commitment to quality control and assurance

- Level of technical support and customer service

- Cost and pricing structure

By evaluating these factors and your specific needs, you can find a reliable manufacturer. They will provide quality reamers and excellent service, ensuring your project's success.

Conclusion: Making an Informed Choice for Your Reaming Solutions

Choosing the right reamer manufacturers is crucial for your projects. Top reamer providers in the United States bring expertise, advanced technologies, and tailored solutions. Look at material quality, precision, and customer support to find the best.

FAQ

What are the different types of precision reamers available?

Precision reamers come in many types. You can find carbide, high-speed steel, and specialty reamers. Each type has its own benefits for different industries.

What manufacturing standards and quality control measures are in place for reamer production?

Top reamer makers follow strict standards and quality checks. This ensures their tools are top-notch, precise, and perform well.

What advanced production technologies are used in modern reamer manufacturing?

Modern reamer makers use the latest tech. This includes CNC machining and computer-aided design. It helps them make tools with high precision and efficiency.

Who are the leading reamer manufacturers in the United States?

In the U.S.,

What are the essential features of premium quality reamers?

Top reamers are made of durable materials. They have precise tolerances and can finish surfaces well. These features mean they last longer and work better in many tasks.

What kind of custom solutions do top reamer manufacturers offer?

Leading makers offer custom reamers for specific needs. They design and make reamers for unique industries or projects.

What are the industry applications and specialized requirements for reamers?

Reamers are used in many fields like auto and aerospace, medical, and general industry. Each field has special needs, like material fit and finish quality. Reamer makers must meet these to perform well.

What factors should be considered when selecting a reamer manufacturer?

When picking a reamer maker, look at their standards, cost, and service. Evaluating these helps find the best match for your needs.