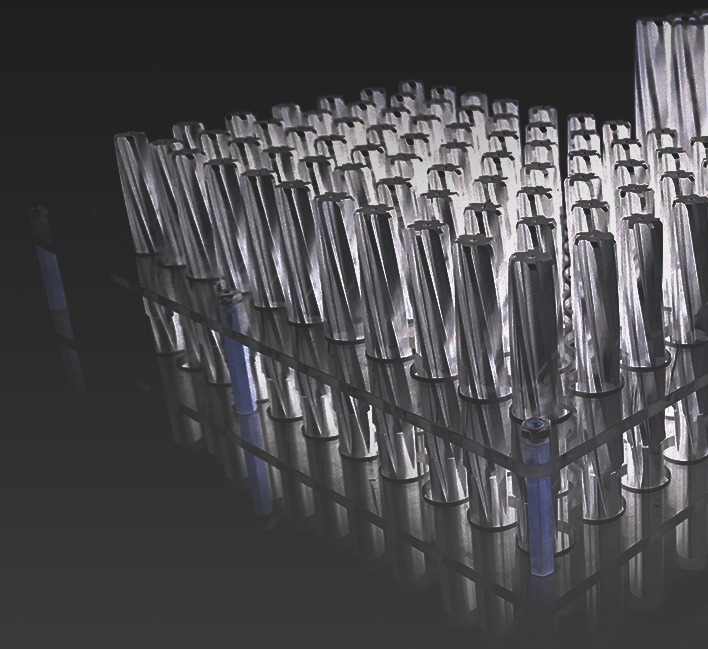

Adjustable Reamer Series

Model:AR

Features

- The Adjustable Hand Reamer is designed to fulfill the requirements of a section of the Engineering Industry which has need of a versatile tool capable of reaming a small number of odd size holes. The Reamer being simple in design and free from complications is easily adjusted to any diameter within the limits of the expansion range and by use of a set of Reamers holes of any size and tolerance from 15/64" to 3-11/32" or 5,95mm to 85mm can be obtained.

- Adjustment is a simple operation carried out by the loosening of one nut while tightening the other, thus allowing the blades to progress along the taper bottomed slots resulting in an increase or decrease in the Reamer diameter according to the direction of adjustment.

- All around type corresponding to the work that is wide from cast iron to steel and SUS, Aluminum and Copper Alloys.

- ★This product is only suitable for 「through hole」 processing.

Specifications

(m/m)

| Size | Range of Adjustment (mm) / (Inch) | Overall Length | Blade Length | Shank / Square | Shank / Diameter | No. of Blades | Weight (g) |

|---|---|---|---|---|---|---|---|

| AR 9A | 5.95 – 6.35 / (15/64 – 1/4) | 91 | 32 | 2.5 | 3.3 | 4 | 12 |

| AR 8A | 6.35 – 7.15 / (1/4 – 9/32) | 83 | 35 | 2.8 | 3.6 | 4 | 12 |

| AR 7A | 7.15 – 7.95 / (9/32 – 5/16 ) | 91 | 35 | 3.2 | 4.0 | 4 | 16 |

| AR 6A | 7.95 – 8.70 / (5/16 – 11/32 ) | 107 | 38 | 4.0 | 5.0 | 4 | 26 |

| AR 5A | 8.70 – 9.50 / (11/32 – 3/8) | 112 | 38 | 4.0 | 5.0 | 4 | 28 |

| AR 4A | 9.50 – 10.25 / (3/8 – 13/32) | 121 | 38 | 4.0 | 5.4 | 6 | 36 |

| AR 3A | 10.25 – 11.00 / (13/32 – 7/16) | 127 | 38 | 4.5 | 6.0 | 6 | 44 |

| AR 2A | 11.00 – 12.00 / (7/16 – 15/32) | 134 | 42 | 5.5 | 6.9 | 6 | 58 |

| AR A | 12.00 – 13.50 / (15/32 – 17/32) | 141 | 42 | 5.5 | 7.3 | 6 | 70 |

| AR B | 13.50 – 15.0 / (17/32 – 19/32) | 146 | 45 | 6.5 | 8.2 | 6 | 88 |

| AR C | 15.00 – 16.75 / (19/32 – 21/32) | 166 | 53 | 7.0 | 9.0 | 6 | 124 |

| AR D | 16.75 – 18.25 / (21/32 – 23/32) | 172 | 56 | 8.0 | 10.5 | 6 | 170 |

| AR E | 18.25 – 19.75 / (23/32 – 25/32) | 178 | 64 | 9.0 | 11.8 | 6 | 224 |

| AR F | 19.75 – 21.50 / (25/32 – 27/32) | 188 | 67 | 10.0 | 13.3 | 6 | 292 |

| AR G | 21.50 – 23.75 / (27/32 – 15/16) | 204 | 76 | 12.0 | 14.8 | 6 | 384 |

| AR H | 23.75 – 27.00 / (15/16 – 1 1/16) | 230 | 83 | 13.0 | 16.4 | 6 | 518 |

| AR I | 27.00 – 30.25 / (1 1/16 – 1 3/16) | 254 | 86 | 15.0 | 19.0 | 6 | 746 |

| AR J | 30.25 – 34.25 / (1 3/16 – 1 11/32) | 280 | 98 | 15.0 | 19.0 | 6 | 884 |

| AR K | 34.25 – 38.00 / (1 11/32 – 1 1/2) | 305 | 109 | 17.0 | 22.0 | 6 | 1302 |

| AR L | 38.00 – 46.00 / (1 1/2 – 1 13/16) | 356 | 113 | 21.0 | 27.0 | 6 | 2044 |

| AR M | 46.00 – 56.00 / (1 13/16 –2 7/32) | 407 | 128 | 26.0 | 34.0 | 6 | 3480 |

| AR N | 56.00 – 70.00 / (2 7/32 – 2 3/4) | 457 | 124 | 32.0 | 42.0 | 6 | 6060 |

| AR O | 70.00 – 85.00 / (2 3/4 – 3 11/32) | 509 | 135 | 38.0 | 51.0 | 6 | 9762 |