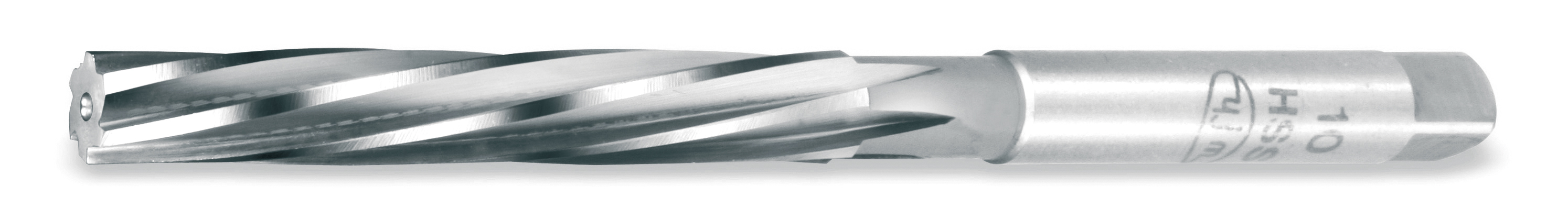

HSS Hand Reamer

Model:HR / HR-M /HRSP

Features

- HRC ≧ 63~64。

- Roundness ≦3µm。

- For hole finishing of cast iron , steels , SUS, Aluminum and Copper Alloys.

- Most generally recommended reamer among other HSS reamers.

- Straight Flute / Spiral Flute

- ★This product is only suitable for 「through hole」 processing.

Specifications

(m/m)

| ΦD Diameter (+0~+5μm) | Flute Length | Overall Length | Chamfer Length | Shank Length | Number of Flutes |

|---|---|---|---|---|---|

| HR 2.900 ~ 2.955 | 40 | 72 | 8 | 23 | 6 |

| HR 3.000 ~ 3.105 | 40 | 72 | 8 | 23 | 6 |

| HR 3.110 ~ 3.605 | 40 | 75 | 8 | 26 | 6 |

| HR 3.610 ~ 4.005 | 40 | 80 | 8 | 30 | 6 |

| HR 4.010 ~ 4.105 | 40 | 80 | 9 | 30 | 6 |

| HR 4.110 ~ 4.605 | 45 | 85 | 9 | 30 | 6 |

| HR 4.610 ~ 5.005 | 45 | 90 | 9 | 35 | 6 |

| HR 5.010 ~ 5.105 | 45 | 90 | 10 | 35 | 6 |

| HR 5.110 ~ 5.605 | 45 | 95 | 10 | 38 | 6 |

| HR 5.610 ~ 5.995 | 50 | 100 | 10 | 38 | 6 |

| HR 6.000 ~ 6.605 | 50 | 100 | 10 | 38 | 6 |

| HR 6.610 ~ 6.995 | 55 | 105 | 11 | 42 | 6 |

| HR 7.000 ~ 7.105 | 55 | 105 | 11 | 42 | 6 |

| HR 7.110 ~ 7.605 | 55 | 110 | 11 | 42 | 6 |

| HR 7.610 ~ 7.905 | 60 | 115 | 11 | 42 | 6 |

| HR 7.910 ~ 7.995 | 60 | 115 | 12 | 42 | 6 |

| HR 8.000 ~ 8.105 | 60 | 115 | 12 | 42 | 6 |

| HR 8.110 ~ 8.605 | 60 | 120 | 12 | 45 | 6 |

| HR 8.610 ~ 8.905 | 65 | 125 | 12 | 45 | 6 |

| HR 8.910 ~ 8.995 | 65 | 125 | 13 | 45 | 6 |

| HR 9.000 ~ 9.605 | 65 | 125 | 13 | 45 | 6 |

| HR 9.610 ~ 9.905 | 70 | 130 | 13 | 45 | 6 |

| HR 9.910 ~ 9.995 | 70 | 130 | 14 | 45 | 6 |

| HR 10.000 ~ 10.105 | 70 | 130 | 14 | 45 | 6 |

| HR 10.110 ~ 10.605 | 70 | 135 | 14 | 50 | 6 |

| HR 10.610 ~ 10.905 | 75 | 140 | 14 | 50 | 6 |

| HR 10.910 ~ 11.105 | 75 | 140 | 15 | 50 | 6 |

| HR 11.110 ~ 11.605 | 75 | 145 | 15 | 54 | 6 |

| HR 11.610 ~ 12.105 | 75 | 150 | 15 | 58 | 6 |

| HR 12.110 ~ 12.605 | 80 | 155 | 16 | 62 | 6 |

| HR 12.610 ~ 13.105 | 80 | 160 | 16 | 62 | 8 |

| HR 13.110 ~ 14.105 | 85 | 165 | 17 | 62 | 8 |

| HR 14.110 ~ 14.605 | 90 | 170 | 18 | 62 | 8 |

| HR 14.610 ~ 15.105 | 90 | 175 | 18 | 66 | 8 |

| HR 15.110 ~ 16.105 | 95 | 185 | 19 | 70 | 8 |

| HR 16.110 ~ 17.105 | 100 | 190 | 20 | 70 | 8 |

| HR 17.110 ~ 18.105 | 105 | 200 | 21 | 75 | 8 |

| HR 18.110 ~ 19.105 | 105 | 210 | 21 | 85 | 8 |

| HR 19.110 ~ 20.105 | 110 | 220 | 22 | 88 | 8 |

| HR 20.110 ~ 21.105 | 120 | 230 | 22 | 88 | 8 |

| HR 21.110 ~ 22.105 | 120 | 235 | 22 | 90 | 8 |

| HR 22.110 ~ 23.105 | 130 | 250 | 22 | 95 | 8 |

| HR 23.110 ~ 24.105 | 130 | 255 | 22 | 100 | 8 |

| HR 24.110 ~ 25.105 | 130 | 260 | 23 | 102 | 8 |

| HR 25.110 ~ 26.105 | 140 | 270 | 23 | 102 | 8 |

| HR 1 / 8” | 40 | 72 | 8 | 23 | 6 |

| HR 3 / 16” | 45 | 90 | 9 | 35 | 6 |

| HR 1 / 4” | 50 | 100 | 10 | 38 | 6 |

| HR 5 / 16” | 60 | 115 | 12 | 42 | 6 |

| HR 3 / 8” | 70 | 130 | 13 | 45 | 6 |

| HR 7 / 16” | 75 | 140 | 15 | 50 | 6 |

| HR 1 / 2” | 80 | 160 | 16 | 62 | 8 |

| HR 9 / 16” | 90 | 170 | 18 | 62 | 8 |

| HR 5 / 8” | 95 | 185 | 19 | 70 | 8 |

| HR 11 / 16” | 105 | 200 | 21 | 75 | 8 |

| HR 3 / 4” | 105 | 210 | 21 | 85 | 8 |

| HR 13 / 16” | 120 | 230 | 22 | 88 | 8 |

| HR 7 / 8” | 130 | 250 | 22 | 95 | 8 |

| HR 15 / 16” | 130 | 255 | 22 | 100 | 8 |

| HR 1” | 140 | 270 | 23 | 102 | 8 |